Contact:Sherry Zhou

Phone:+86-18917398894

E-mail:sherry.z@naboer.com.cn

Add:Rm706, Building A6 ,Hefei Financial Port, Yangzijiang Road, Baohe District, Hefei City, Anhui Province, China

Переключиться на русскую версию

Welcome to Anhui Nabor Mechanical and Electrical Equipment Co., Ltd.

Bosch Rexroth

R900753378

4WEH16E7X/6EG24N9ETK4/10B10

DIRECTIONAL SPOOL VALVE

DIRECTIONAL SPOOL VALVE

Description

The Bosch Rexroth 4WEH16E7X/6EG24N9ETK4/10B10 (R900753378) is a high-performance industrial hydraulic valve designed for reliable control of oil flow direction in various hydraulic systems. This spool valve is pilot-operated, with an internal pilot oil supply and return, ensuring smooth operation. It features a size E spool with an electrical connection that includes a PE connector pole according to EN standards. The valve operates with a maximum pressure capability and utilizes solenoid actuation for precise control. It is designed for subplate mounting and adheres to the NFPA T3.5.1 R2 D03 size CETOP D standards, as well as the ISO 4401 porting pattern. The supply voltage required for this model is 24 VDC, and it offers multiple switching positions for versatile application use. Equipped with NBR seals, the 4WEH16E7X/6EG24N9ETK4/10B10 valve can handle a variety of hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, and HFC types. Its construction ensures durability and reliability in controlling fluid dynamics within hydraulic systems. This directional spool valve from Bosch Rexroth is an essential component for applications requiring precise control over start, stop, and direction of fluid flow. With its robust design and electrohydraulic actuation capabilities, it is well-suited for demanding industrial environments where consistent performance and longevity are critical.

DIRECTIONAL SPOOL VALVE 4WEH16E7X/6EG24N9ETK4/10B10

Size 16, symbol E, electrical with solenoid, 24 V DC

Industrial hydraulic valve in a high performance range. Reliable switching of the oil flow direction according to hydraulic symbol.

Unpacked Weight: 10.211 kg

Types of actuation (internal or external pilot control): Electro-hydraulic (type WEH) For subplate mounting Porting pattern according toISO 4401 4/3-, 4/2- or 3/2-way version Spring or pressure centering, spring end position or hydraulic end position Wet-pin DC or AC solenoids, optional Electrical connection as individual or central connection Optional versions:

- Manual override

- Switching time adjustment

- Preload valve in channel P of the main valve

- Stroke setting and/or spool position monitoring

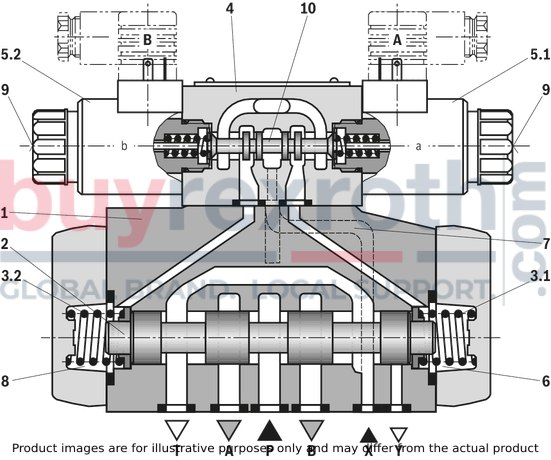

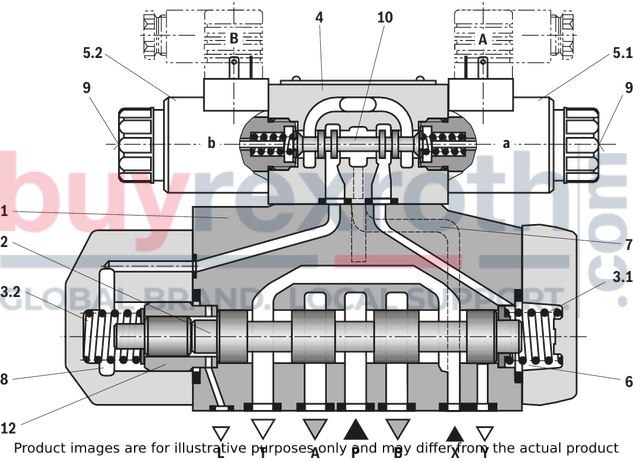

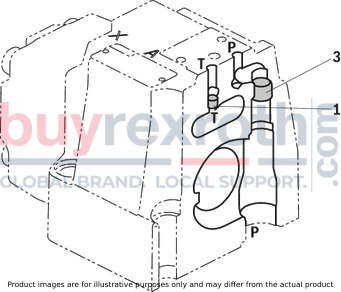

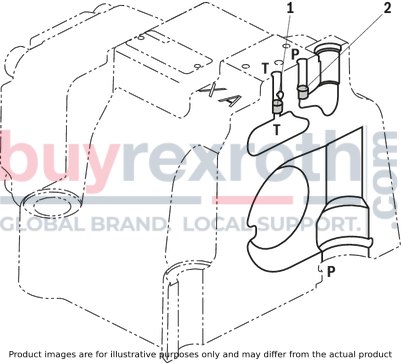

The valve type WEH is a directional spool valve with electro-hydraulic actuation. It controls the start, stop and direction of a flow. The directional valve basically consists of the main valve with housing (1), the main control spool (2), one or two return springs (3.1) and (3.2), as well as the pilot control valve (4) with one or two solenoids "a" (5.1) and/or "b" (5.2). The main control spool (2) in the main valve is held in the zero or initial position by the springs or by means of pressurization. In the initial position, the two spring chambers (6) and (8) are connected with the tank in a depressurized form via the pilot control valve (4). Via the control line (7), the pilot control valve is supplied with pilot oil. Supply can be implemented internally or externally (externally via port X). Upon actuation of the pilot control valve, e.g. solenoid "a", the pilot control spool (10) is moved to the left and thus, the spring chamber (8) is pressurized with pilot pressure. The spring chamber (6) remains depressurized. The pilot pressure acts on the left side of the main control spool (2) and moves it against the spring (3.1). This connects port P with B and A with T in the main valve. On switching off of solenoid, the pilot control spool (10) returns to its initial position (except impulse spool). The spring chamber (8) is unloaded to the tank. The pilot oil return is implemented internally (via channel T) or externally (via channel Y). An optional manual override (9) allows for moving of the pilot control spool (10) without solenoid energization.

The return springs (3.1) and (3.2) in the spring chambers (6) and (8) hold the main control spool (2) in central position without pilot pressure even with, for example, vertical valve positioning.

Due to the design principle, internal leakage is inherent to the valves, which may increase over the life cycle.

4/3 directional valve with pressure centering of the main control spool, type WEH…H

The main control spool (2) in the main valve is kept in the zero position by pressurization of the two front faces. One centering bush (12) rests on the housing and fixes the control spool position. By pressure relief of one front face, the main control spool (2) is moved to the switching position. The unloaded control spool face displaces the returning pilot oil into channel Y (external) via the pilot control valve.

The springs (3.1) and (3.2) do not have a return function in this version. They hold the main control spool (2) in central position in the depressurized condition and with horizontal installation.

NG10

NG16

NG25 („W.H 22“)

NG25 („W.H 25“)

Size 32

Pilot oil supply | Pilot oil return | ||

External | 2 closed | External | 1 closed |

Internal | 2 open | Internal | 1 open |

1 | Plug screw M6 according to DIN 906, wrench size 3 - Pilot oil return |

2 | Plug screw M6 according to DIN 906, wrench size 3 - Pilot oil supply |

3 | Plug screw M12 x 1.5 according DIN 906, wrench size 6 |

The pilot oil supply is implemented externally - via channel X - from a separate pressure supply.

The pilot oil return is implemented externally - via the Y channel - into the tank.

The pilot oil supply is implemented internally from channel P of the main valve. (see Technical data)

The pilot oil return is implemented externally - via channel Y - into the tank. In the subplate, port X is closed.

The pilot oil supply is implemented internally from channel P of the main valve.

The pilot oil return is implemented internally via the channel T - into the tank. In the subplate, ports X and Y are closed.

The pilot oil supply is implemented externally - via channel X - from a separate pressure supply.

The pilot oil return is implemented internally - via the channel T - into the tank. In the subplate, port Y is closed.

Throttle insert

Use of the throttle insert (5) is necessary if the pilot oil supply in channel P of the pilot control valve is to be limited (see below). The throttle insert (5) is inserted in channel P of the pilot control valve.

Notices:

The modification of the pilot oil supply may only be performed by authorized specialists or at the factory!

Pilot oil supply X or return Y external: The maximum admissible operating parameters of the pilot control valve must be observed (see data sheet 23178)! Maximum pilot pressure: please observe the Technical data! Pilot oil supply internal (version "ET" and "E"): Minimum pilot pressure: please observe the Technical data! In order to prevent inadmissibly high pressure peaks, a "B10" throttleinsert has to be provided in port P of the pilot control valve. In connection with version "H", the pressure reducing valve "D3" (see switching time adjustment) is also required.

3 | Pilot control valve |

4 | Main valve |

5 | Throttle insert |

Features

| Internal pilot oil supply, internal pilot oil return |

| Spool valve |

| Pilot-operated |

| Size 10 … 32 |

| Maximum operating pressure 350 bar |

| Maximum flow 1100 l/min |

| Component series 4X, 7X, 6X |

Contact:Sherry Zhou

Phone:+86-18917398894

E-mail:sherry.z@naboer.com.cn

Add:Rm706, Building A6 ,Hefei Financial Port, Yangzijiang Road, Baohe District, Hefei City, Anhui Province, China